Selective Soldering Challenges and Meeting Training Needs

Selective Soldering Challenges and Meeting Training Needs

Authored By: Dr. Samuel J. McMaster*1,2, Kane F. Witham*1, Professor Andrew Cobley*2, Dr. John E. Graves*2, Eddie Groves*3

1 – Pillarhouse International Ltd., Rodney Way, Chelmsford, CM1 3BY, UK

2 – Functional Materials and Chemistry Research Group, Research Centre for Manufacturing and Materials, Institute of Clean Growth and Future Mobility, Coventry University, Priory Street, Coventry CV1 5FB, UK

3 – Selective Soldering Academy, 201 Lively Blvd, Elk Grove Village, IL 60007

1. Introduction

Selective soldering has grown in popularity over the past 25 years to now be a major connective technology in the electronics industry. The machines and techniques have progressed to being a major feature of in-line processes with the ability to flux, pre-heat[1] and solder through-hole technology (THT) components for printed circuit boards (PCBs) within a single machine or series of modular machines. As described by McMaster et al. [1], there are 2 classes of selective soldering machines: hand-load and in-line machines. As in-line systems are used for processing either a greater volume of boards or larger boards, many of the most challenging selective soldering processes are undertaken with this equipment.

[1] Typically fluxing will be applied before pre-heating for PCB solder processing so that the temperature of the pre-heat step can activate the flux.

2. Challenges in selective soldering

Broadly, the challenges in selective soldering can be described as fitting into two main categories. The first of which is process requirements wherein a particular printed circuit board must be processed within a specific timeframe to meet the defined production schedule. The second of the challenges is the soldering of boards with increasing complexity of design, large amounts of surface mount components and high thermal mass. The following sections will discuss each of these challenges in more detail.

2.1. Process challenges

Multiple elements make up a selective soldering process [2]. The first of which is generally the fluxing step. Fluxing fulfils several purposes for the selective soldering process:

- Creating a film between the solder mask and the solder to avoid the adherence of solder to the PCB.

- Cleaning the metal surfaces of components to remove oxides to make soldering possible.

- Promotes the wetting of the solder for better hole fill.

- Aids in the prevention of solder bridges and solder balls.

There is no one size fits all flux; they can be alcohol-based, water-based or rosin based. Solid content can vary as can the active chemistry. Application methods can vary depending upon the process requirements but generally, two methods are used. The drop-jet can quickly apply miniature droplets in a precise fashion. Water and alcohol-based fluxes can be used with the drop-jet. When a larger area is to be soldered, an ultrasonic head is used. This fluxing module is lower maintenance and can handle higher solids content fluxes.

After fluxing, the board would generally be pre-heated. This activates the chemistry and prepares the board to better wet the applied solder. Most commonly, infrared (IR) lamps are used with a wavelength between 750 nm and 3000 nm. Balancing the wavelength of the IR with the absorption of heat of the parts is key. IR can quickly respond (1-3 seconds) to heat the board and can be used in closed loop mode (taking a temperature reading and altering the power to hit a desired thermal profile) or open loop (where the lamps simply heat the assembly without imposed power control)

For thicker boards, convection heating may be used. This technology is slower to respond than IR resulting in pre-heating steps in the range of multiple minutes compared to 1-2 minutes for IR. Convection is, however, able to evenly heat thicker PCBs and isn’t bound by the reflectivity issue of different wavelengths of IR lamps.

To achieve the optimal pre-heating for a specific product, a thermal profiler should be used to determine the maximum temperature, thermal ramp rate and pre-heating time. For some processes, the PCB is then enough that pre-heating doesn’t need to be used and the heating from the applied solder is enough. The order of fluxing and pre-heating can be changed depending on the process requirements for the board and depending upon the flux being used. As heating is applied to the board, a water-based flux will spread whereas an alcohol-based flux will begin to evaporate. Proper process engineering ensures that the order and timings of these processes are specified.

Following these steps, it’s finally time for soldering. As with all the other elements of the selective process, there are multiple parameters and options to consider during this step:

- Inertion: To maintain good flow characteristics and reduce the amount of bridging, a low-oxygen environment is used. Nitrogen is typically used for inertion to achieve sub 10 ppm of oxygen. 50 ppm of oxygen is the maximum permissible limit, above this the solder quality is affected and dross is generated at a higher rate.

- Positioning of the solder bath[2]: The bath positioning can be used to either apply soldering to a single joint or closely packed series of joints in a dip step or movement along the underside of a PCB. The machine can be programmed for rows of connectors as part of a draw step.

- Contact time of solder: Greater contact time can aid wetting and pull-through of solder but increasing the time can dissolve copper from the PCB.

- Type of solder: lead-free or leaded; inclusion of additives to alter the liquid properties or the mechanical properties of the solidified joint.

- Use of wetting or non-wetting nozzles: non-wetting dip nozzles can be used for fast production of high-volume products, but they lose the per-joint customisation of a wetting nozzle.

- Top-side heating during soldering: used if the assembly has a high thermal mass that required continuous heating to ensure good solder pull-through.

- Solder temperature: The soldering temperature is chosen to balance good pull-through, flux activation loss and increased likelihood of oxidation. Generally, the temperature will be in the range of 280-320 °C.

- Board warp correction: the application of heat to the PCB can warp it enough to affect the soldering process. The use of a laser positioning sensor can apply live offsets to the programmed height to achieve good soldering.

[2] Pillarhouse typically employs a fixed PCB during soldering with a moving soldering bath and nozzle.

Nozzle size and type can be customised for specific joints but there correct programming must still be utilised as there are so many parameters that interact to produce a well-soldered joint. With new materials engineering, the maintenance can be reduced as with the AP Master nozzles [3,4]. The increased wetting enabled by surface engineering technologies allows for faster start-up of the nozzles, easier rewetting and less dewetting during process. Cleaning is still essential to keep a nozzle running well no matter the material design[3].

[3] Nozzles are also cleaned with flux however a different chemistry is utilized to remove the oxides that form on the surface of the ferrous materials utilized as nozzles.

A unique item that poses a challenge is not, in fact, an issue of process technology but is more people-centred. No one likes doing maintenance, but it is essential to keep all machines working properly. Machine wear out is inevitable. Proactive maintenance is undoubtedly better for a full production environment but this is more time intensive and requires greater planning [5].

Sometimes nozzle sizes are chosen to fulfil the requirements of multiple products. In this case, it is often more optimal to use planned machine downtime to swap to a different nozzle size to produce better soldering quality. This takes more time and planning from maintenance staff, however. Some customers will opt to use a heated bath trolley to allow for faster changing of baths (to use different solders or a different nozzle geometry). The heating function also allows maintenance to be carried out of the baths outside of the soldering system; when the bath cools the impeller chamber is frozen, so it is inaccessible.

Finally, electronics manufacturing is becoming increasingly automated, and the soldering systems must be adapted to fully integrate with this new paradigm of manufacturing. Examples include the use of robot arms to load PCBs into the machines, re-soldering in in-line soldering machines based on optical inspection results and automated nozzle conditioning and solder top-up systems.

2.2. Board-specific challenges

Often Pillarhouse engineers will encounter PCBs where little consideration has been given to the end manufacture process. As selective soldering will be viewed as the last element of the manufacturing chain, it is the last thing a design team may think about. Furthermore, many design teams may not be experienced with optimal design elements to enable fast processing with selective soldering. Often extended nozzles need to be used to work around tall components. Additionally, customers will approach Pillarhouse with boards that were built with surface mount technology (SMT) assembly in mind necessitating the use of smaller nozzles with more precise programming.

With the rapid increase in electric vehicle systems, there has been an increase in PCBs bonded to larger cooling assemblies which pose a challenge in terms of pre-heat as well as soldering larger components such as insulated-gate bipolar transistors (IGBTs).

These board-specific challenges require careful setting of process parameters to ensure good soldering within the time requirements. This involves setting the pump speed to achieve the correct level of solder fill and ensuring the nozzle remains wetted, programming the optimal vectoring of the solder bath and pull-off characteristics to reduce bridging.

3. The Selective Soldering Academy (SSA)

Due to the level of adoption of selective soldering technologies and their importance in the circuit board assembly process, it’s now more likely that you will find more assembly facilities with it than without[6]. To be able to maintain and run a selective soldering machine and overcome the challenges described above, training is essential.

The SSA exists to train anyone (not just those with Pillarhouse equipment) on the correct practices for running equipment, maintenance and how to approach programming new boards to enable customers to set up new processes quickly, keep them running and maximise the financial impact of the selective soldering process.

4. The SSA Challenge Board

The main teaching element of the SSA is the Challenge board. It’s unlikely that a real-world soldering process will possess all the elements in this PCB; function is not the aim of this board, it is designed to be difficult to solder and it’s impossible to successfully solder all elements with one type of nozzle.

The board is 0.075” (1.91 mm) thick with 4.2 oz (56.7 g) copper layers. Two of the layers are ground planes while the other two have only traces. Some connections to the ground planes are heat relieved.

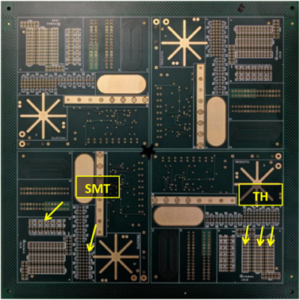

Silkscreen is used to partition each area of the board and each section is numbered to help identify the specific techniques to be used in each. SMT and THT are on both the board’s top and bottom sides. Figure 1 shows the bottom-side of the PCB which is the starting point for THT soldering.

Figure 1. Bottom-side view of the SSA Challenge board.

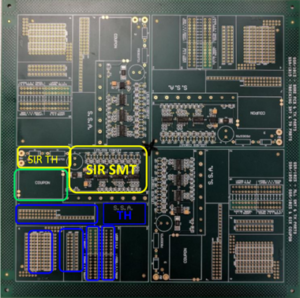

Figure 2 shows the top side of the PCB. Unlike the bottom-side, the top-side SMT and some nearby THT parts are functional and are highlighted in yellow. This is part of the surface insulation resistance (SIR) test area. There is also a simulated SIR coupon to be soldered to the board in the green highlighted area.

Figure 2. Top-side view of the SSA Challenge board.

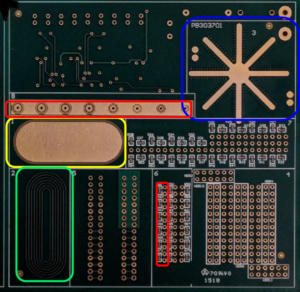

Figure 3 shows a close-up image of one of the test areas on the bottom-side of the board. The red highlighted areas are for practising soldering using the micro-nozzle allowing you to solder near metallised areas or SMT components. The blue area is to test the effectiveness of fluxes for solder spreading; the cross pattern is used to highlight the spreading further. The yellow area is to test the wetting performance of flux on a bare metal finish. A solder draw can be programmed on this area to observe solder wetting and spreading. Finally, the green area is used to observe flux wetting on solder mask.

Figure 3. Closeup of solder and flux test areas.

5. Conclusions and future developments

Selective soldering has now reached a stage of maturity where it can be considered its own processing technology. As a result of this, PCBs should be designed with this processing technology in mind however the innovations in selective soldering (e.g., the micro-nozzle) can mitigate against designs where this is not possible. Experienced and knowledgeable staff will be able to program process conditions to maximise the potential of selective soldering. Emerging markets such as electric vehicles have shown that selective soldering technologies continue to grow in popularity. The AP Master Nozzle technology will enable increased soldering capabilities and easier maintenance of wettable nozzles to help meet the demands of growing markets.

For more information on Pillarhouse International’s AP Master Nozzle, read here: Selective Soldering: A Need For Innovation and Development (pillarhouse.co.uk)

References

[1] S.J. McMaster, A. Cobley, J.E. Graves, N. Monk, Selective Soldering: A need for Innovation and Development, J. Inst. Circuit Technol. 15 (2022). https://instct.org/news/journals/ict-journal-vol-15-no-3#paper_2 (accessed October 23, 2022). [2] J. Bath, Lead-free Soldering Process Development and Reliability, Wiley, 2020. [3] S.J. McMaster, A. Cobley, J.E. Graves, N. Monk, Selective soldering nozzles: insights into wear mechanisms and future developments, in: IPC APEX Tech. Conf. Proc., San Diego, 2023. [4] Selective soldering nozzles: insights into wear mechanisms and future developments, 2023. https://youtu.be/w5MaHJxQ_J0 (accessed May 22, 2023). [5] M.G. Deighton, Maintenance Management, in: Facil. Integr. Manag., Elsevier, 2016: pp. 87–139. https://doi.org/10.1016/B978-0-12-801764-7.00005-X. [6] Selective Soldering Academy, About – SSA – Selective Soldering Academy, (2023). https://solderingacademy.com/about/ (accessed May 18, 2023).[1] Typically fluxing will be applied before pre-heating for PCB solder processing so that the temperature of the pre-heat step can activate the flux.

[2] Pillarhouse typically employs a fixed PCB during soldering with a moving soldering bath and nozzle.

[3] Nozzles are also cleaned with flux however a different chemistry is utilized to remove the oxides that form on the surface of the ferrous materials utilized as nozzles.